Optimization of Plunger Lift Systems

Over time, gas wells can experience a phenomenon known as liquid loading, where the accumulation of liquid becomes substantial enough to completely seal the tubing, leading to a cessation of gas production. If left unaddressed, this issue can permanently render the well unproductive.

Plunger Lift, a form of artificial lift, utilizes gas pressure to remove the accumulated liquid from the well’s bottom. Plunger Lift systems have gained widespread popularity due to their cost-effectiveness and efficiency. The typical operation of a Plunger Lift involves a continuous cycle that is repeated to lift the accumulated slug. Presently, plunger cycles are managed using trial-based trigger systems and manual inspections, resulting in suboptimal operation.

Maximize Gas Production

Minimize Equipment Damage and Downtime

Next to Zero Emissions

Reduce Labour Costs

Our Monitoring Platform: Standalone, in the Cloud, or Embedded within Existing Metering and Monitoring Hardware!

Leveraging IoT and Cutting Edge AI Frameworks for Smarter, Cleaner, and Efficient Gas Wells

Benefits

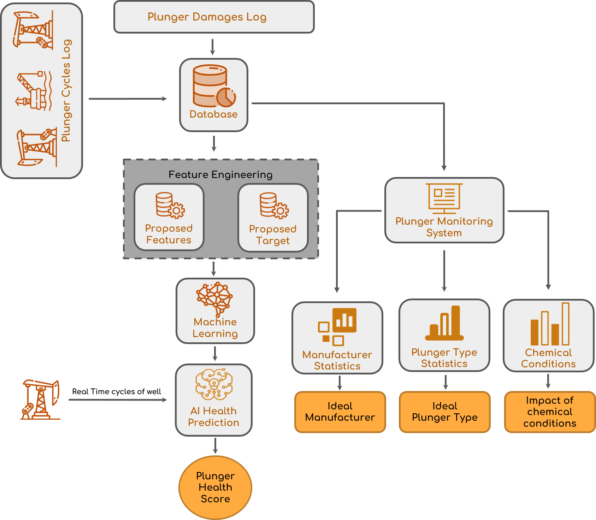

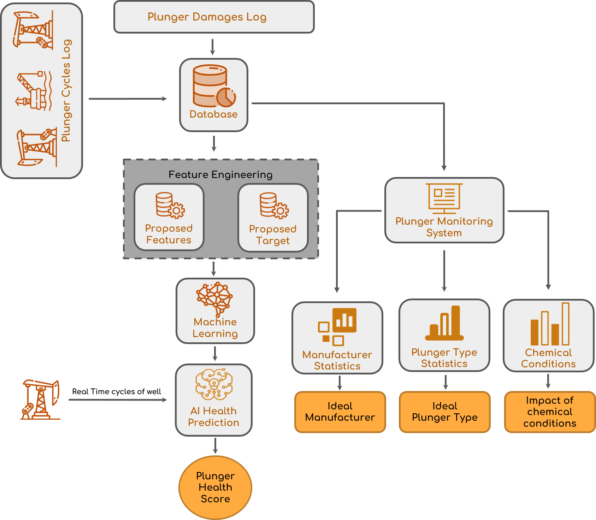

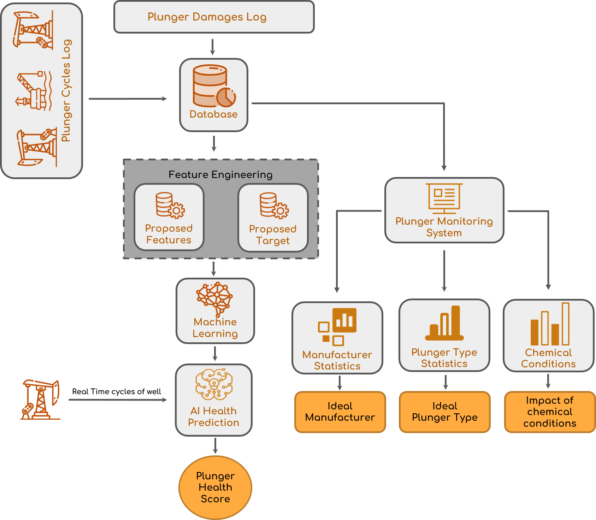

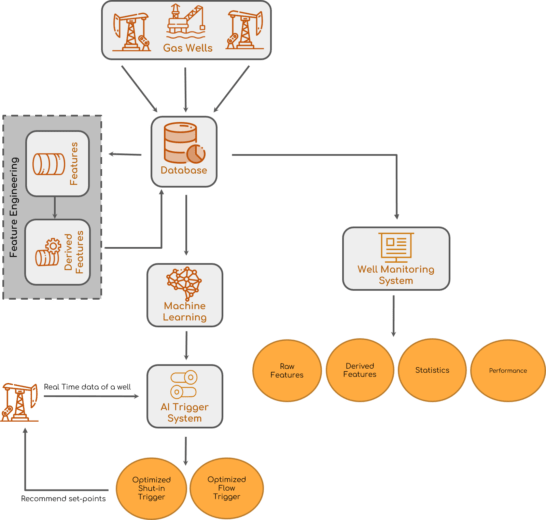

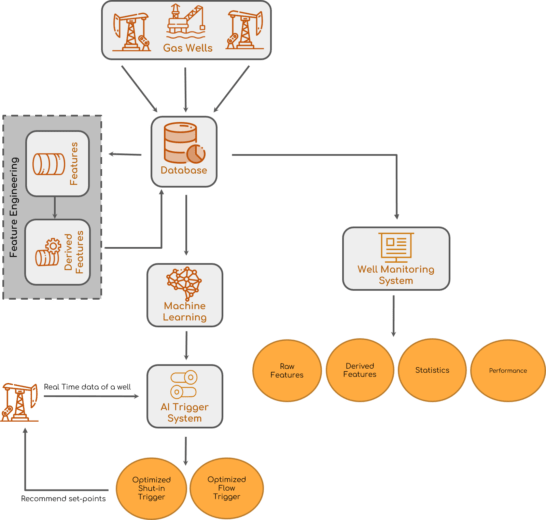

Workflow

Optimizing Plunger Life

Plunger Lift systems are extensively utilized in gas wells due to their cost-effectiveness and similarity in lifting accumulated liquid slugs at the well’s bottom. Various plunger types are available from different vendors.

The selection of an appropriate plunger for a specific well depends on multiple factors, including internal well conditions, path geometry for the plunger’s travel, gas amount and pressure, chemical conditions, and more. It is crucial to make an informed decision when choosing the plunger type and manufacturer for a particular well. Failing to do so can result in a significant increase in plunger breakages and a reduction in plunger lifespan, leading to revenue loss in the form of maintenance and downtime costs.

Optimize plunger performance and minimize replacements with our Data & AI-driven solution. Our solution recommends the most suitable plunger type and manufacturer based on the specific conditions within the well.

Benefits

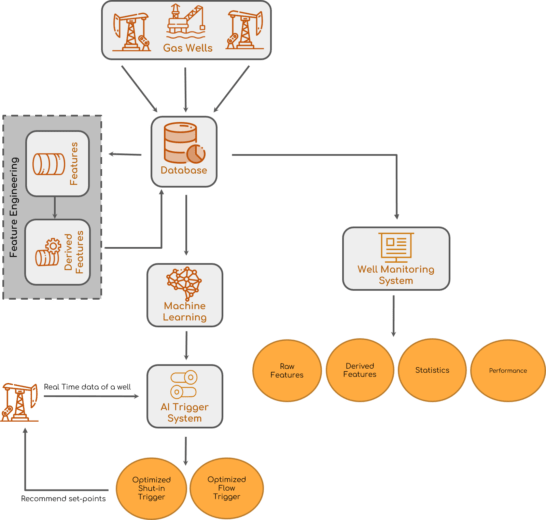

Workflow