Root Cause Analysis for Industrial Plant Faults

Root cause analysis (RCA) serves as a problem-solving methodology that plays a vital role in identifying the underlying causes of faults or issues. Widely employed across various industries, including industrial process control, IT operations, healthcare, aviation, nuclear plants, and rail transport, RCA enables a comprehensive examination of accidents and incidents. Despite its apparent simplicity, RCA faces several challenges that hinder its implementation. The complexity arises from the inability to manually monitor all aspects, the existence of multiple root causes for a single problem, and the intricate nature of causal graphs, which often span multiple levels, making their establishment and querying highly intricate.

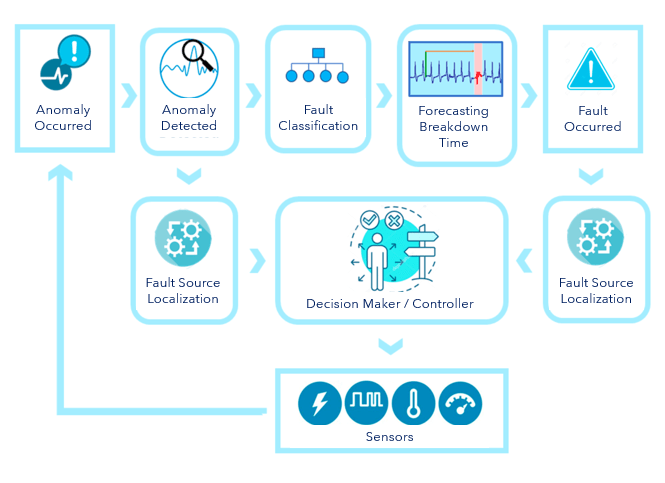

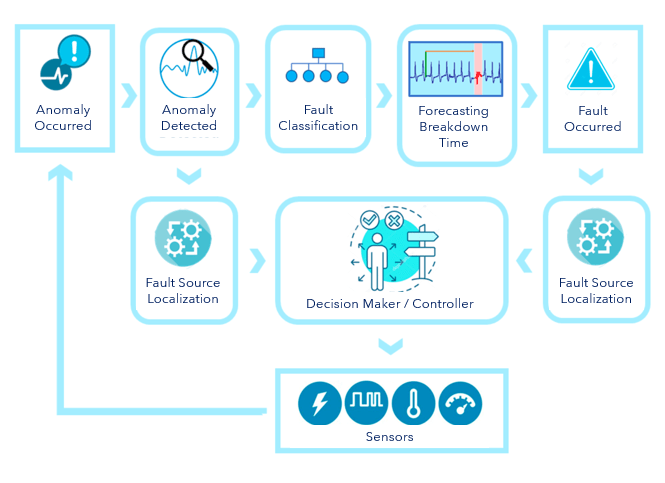

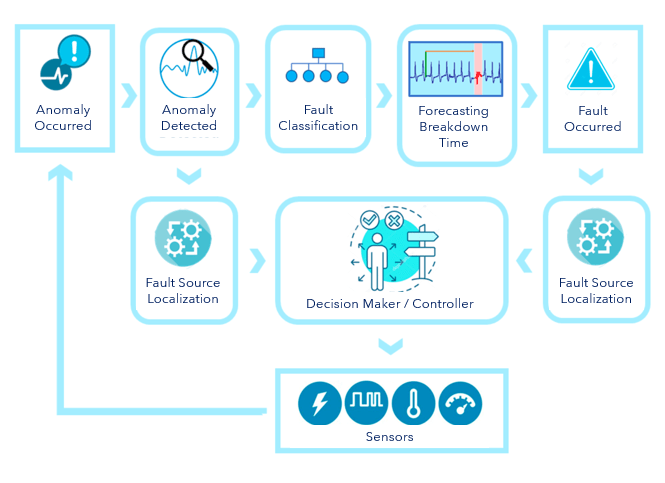

To address these challenges, we have developed an AI-powered solution specifically designed for identifying the root cause and determining the most influential path of faults within industrial plants. Our innovative approach leverages the power of causal Bayesian networks, which learn the structure from plant data and sensor measurements. By utilizing causal inference techniques, we are able to identify causal effects and path-specific effects with precision. Our solution offers flexibility and modularity, facilitating online monitoring of plants, predictive maintenance, and the assessment of how changes in control node values impact other nodes within the plant. Furthermore, our solution accommodates both categorical and numeric variables/nodes, including the handling of latent variables, ensuring comprehensive applicability and accuracy in various industrial settings.